Thermal Anti Icing System Aircraft - Since ice protection systems are mission-critical systems, their design, development, verification and certification fit into the Siemens Xcelerator product design and engineering, model-based systems engineering (MBSE) and verification management digital threads, where Simcenter performance engineering skill tools provide required

engineering data to support aircraft programs and processes. Not only do Simcenter solutions enable the sizing and optimization of the detailed design, but they also provide the elements for the proof of compliance based on virtual and physical test data.

Thermal Anti Icing System Aircraft

This effectively contributes to aircraft program execution excellence by enabling you to stay on time and budget. The temperature is controlled from the flight deck, although many aircraft have the ability to alter the temperature from inside the cabin.

Aircraft Ice Protection Systems Engineering

The temperature selector changes the amount of cool air allowed through the air ducts until a desired temperature is reached. As a critical aspect for the safe operation of an aircraft, wing anti-icing systems must pass a qualification test.

The standard prescribes several dynamic tests, including random, shock and sine excitation tests, to be carried out to study their effect on the parts composing the anti-icing system. Multiple-output, multiple-input (MIMO) technology can help you make sure each excitation point is simultaneously excited with the appropriate loading.

Using this state-of-the-art technique enables test engineers to increase efficiency in the entire vibration qualification process. 'Suck, squeeze, bang, blow': this is the phrase that most people use to describe how an engine works. Known as the Otto cycle, this summarizes the stages of a four-stroke engine that is typically used in a car or a plane.

The engine sucks air through the intake, squeezes it through a series of compressors to raise the temperature and pressure before igniting it and producing energy. As well as eroding compressor blades, oil blockages and internal sump fires, the intake of huge amounts of dust will eventually lead to the cockpit, contaminating the air and causing avionics failures.

Wing Anti-Ice System Testing

This can cause considerable problems in sand-abundant locations, such as Egypt, Hawaii and even Texas. Once both engines are started, the APU can then be switched off as it is no longer needed as a source of bleed air.

But if the APU is unserviceable, the air must be provided externally from a unit on the ground. Possibly the most important use of bleed air is cabin pressurization. As discussed on one of our other blog posts, pressurizing the air within the cabin allows us to breathe at high altitudes without oxygen masks.

So the pressurized air from the engine is a readily available source of pressurized air. Bleed air is used abundantly throughout airliners and helicopters today as it is a readily available source of energy; as long as the engines work, bleed air will be available.

Its useful qualities are heat and pressure. Heat is often used for anti-ice and de-icing systems whereas pressure is used for things like cabin air. When the start sequence is initiated, bleed air is sent from the APU to the accessory gear box which rotates the various shafts within the engine.

Pressurization Air Conditioning

This is when the 'suck-squeeze-bag-blow' sequence begins. Once the combustion stage (Bang) within the engine becomes self-sustaining the igniters are switched off and engine start is complete. This is the most common method of ice protection on big jets.

The Boeing 787 is one exception to this. The Dreamliner uses electro-thermal anti-icing for the leading edge of the wings. This is an ice protection system typically seen on lighter aircraft. These safety-critical systems are part of the certification process and must be considered during the aircraft program development and testing.

An integrated simulation and testing approach enables you to evaluate the performance of ice protection components and systems under ideal and worst-case scenarios. Pneumatic boots haven't changed all that much since their invention over 80 years ago and are fairly lightweight.

Unfortunately they do require regular maintenance. They can crack when exposed to ozone (which is a gas that exists in normal air, but at generally low quantities) and can be subject to punctures if damaged by debris or a bird strike.

What Is Bleed Air?

Lightning may also pose a threat to their integrity. Bleed air is the name given to the air that is 'bled' from the compressor stage of an engine. At this stage the air is around 200-250⁰C and at a medium-high pressure so its energy can be used to power a number of systems, including but not limited to the air conditioning.

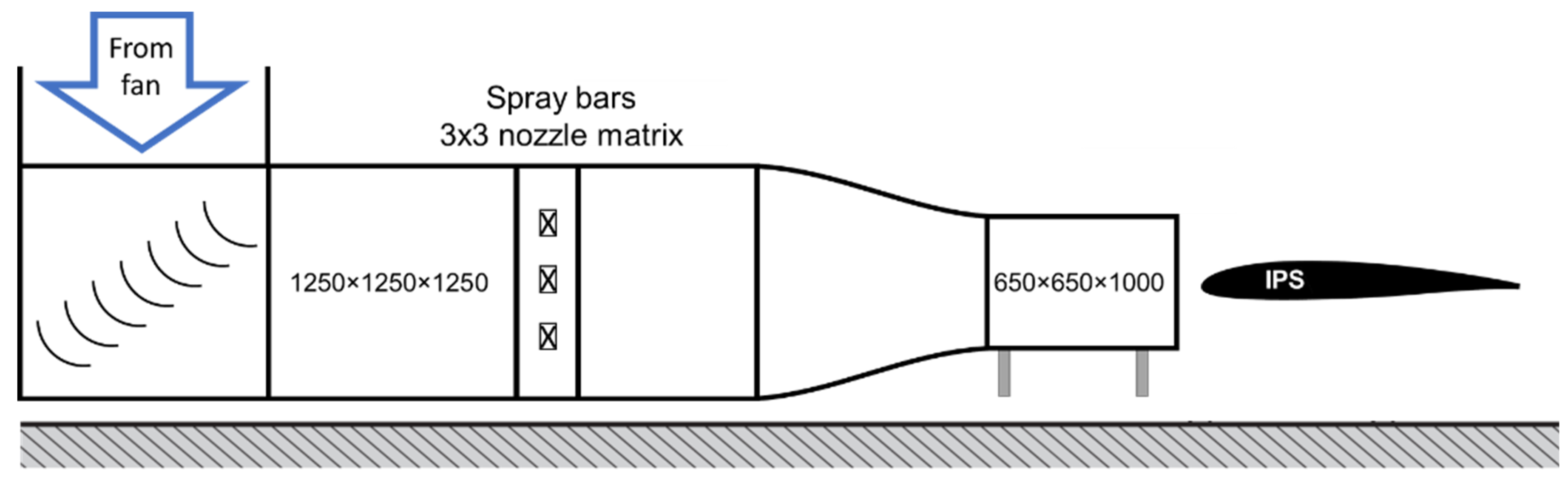

After the system type is chosen and the component sizing is completed using system simulation, the components require a more detailed 3D CFD simulation for their individual performance and optimization. The component performance can then be fed back into or coupled with a system simulation model with more accurate parameters to increase system simulation accuracy.

These aircraft use what is known as 'pneumatic boots' to keep their surfaces ice-free. A 'boot' is a layer of rubber placed on the leading edge of the wing that is inflated with bleed air to temporarily change the shape of the wing and break off any unwanted ice.

Our lightweight and highly-efficient air management solutions monitor and control cabin temperature and air flow in the cockpit, passenger, and cargo areas and also provide secondary cooling for avionics simultaneously. These solutions also manage the aircraft's engine bleed air and provide ice protection for flight control surfaces.

Anti-Icing Component Analysis With Cfd Simulation

Foreign Object Damage or FOD is a very real threat to aircraft of all kinds, but particularly to helicopters. Over time tiny particles such as dirt or sand can accumulate within the engine. This increases the wear on the engine, degrading its performance and ultimately causing the component to fail.

To prevent FOD entering the engine, bleed air is used to move the air radially, introducing a centrifugal force to the intake air and pushing the heavier particles such as sand, dirt and even ice outwards, away from the engine.

They might sound cute, but bubbles in the hydraulic systems are very serious and can cause major failures of pumps and motors. Due to low pressure, the bubbles formed can boil and implode eroding and causing damage to nearby surfaces.

Ice protection systems and components play a crucial role in safe aircraft operation under icing conditions. Icing can damage the aerodynamic shape, increase aircraft drag and reduce its controllability. This impacts flight performance and safety. Such systems are usually installed in wings, nacelle intakes, pitot tubes, stabilizers and propellers and helicopter rotor blades.

Aircraft Ice Protection Systems Simulation And Testing

One pitfall of the bleed air/cabin air system is that any contaminants could potentially be circulated around the cabin. For instance, occasionally hot oil may leak from inside the engine. This 'pyrolized' oil can then mix with the air being fed to the cabin, leading to a burning smell or toxic smoke entering the cabin if the seals have deteriorated.

The auxiliary power unit (APU) is more commonly used however, as external bleed air is not always available. Located at the rear of the aircraft, the APU is essentially a small engine and works in the same way as the larger engines, creating its own bleed air.

With the engines switched off this is the source of the air conditioning. Air is provided to the aircraft via the 'non-starting' engine. This allows pressurized air into the system to begin the necessary rotation for engine start.

Once this first engine is running, the aircraft once again has an onboard source of bleed air which can be used to start the second engine. This is known as a 'cross-bleed' start. Weather insights and forecasts to provide you with the operational intelligence you need to reduce your risk of outage and to prepare ahead of time when an outage cannot be avoided.

System Simulation For Aircraft Ice Protection

Learn more about our Utilities products. EAPS helps to limit FOD ingestion and extends the life of the engine, allowing helicopters to operate in sandy and dusty areas which had previously caused rapid degradation of components.

By installing EAPS they were able to get 6x the lifespan from the engines Additionally if the engines have been washed incorrectly, residue from the toxic cleaner used can cause similar events. As always, crews are trained to deal with these scenarios appropriately to ensure the safety of the crew and passengers but fumes events such as these have raised concerns about the quality of cabin air and the long-term effects it might have on the health of aircrew

. System simulation allows you to define the optimal system sizing earlier in the design cycle. It enables a smooth integration of the resulting aircraft ice protection system with other pneumatic consumers and their coupling with the engine bleed air system.

Moreover, you can perform what-if analyzes like air leaking from a bleed pipe and the impact on the overall system. Without a system to prevent FOD, engine replacements were needed with alarming regularity. In Texas the US Army recorded the average flight time between major overhauls of helicopter engines was 262 hours versus the intended 1200 hours.

Hydraulic System Reservoir Pressurization

That's 2% of the flight time they were expected to reach! Failures of the bleed air system can lead to cabin depressurization such as on one A319 flight from Cape Town to Johannesburg on 7th September 2008. The crew received a failure warning of the engine 1 bleed system and took the appropriate corrective actions.

Nevertheless the cabin altitude began to increase. Bleed air is also useful in conjunction with the hydraulic system. By pressurizing the hydraulic reservoirs, manufacturers are able to prevent cavitation and the damage it causes. Cavitation occurs when the fluid volume demand is greater than the amount of fluid being supplied, leading to bubbles.

Thankfully these incidents are much less frequent on newer aircraft due to new technology such as HEPA filters. These filters use layers of glass and activated carbon-based material to remove 99.7% of particles within the air, including harmful microbes such as COVID-19.

But as already mentioned, bleed air is over 250⁰C when it leaves the engine so it must be cooled via an air-to-air heat exchanger before it can be circulated. This uses cold air from outside the plane and passes it over the hot bleed air until the desired temperature is reached.

Engine Start

Developing anti-icing and de-icing systems from component level to systems integration should be considered early in the design stage to stay on budget and schedule. Simulation and testing play a major role in the development and certification process to ensure flight safety under icing conditions.

The crew then had to make an emergency descent according to their standard procedures until they reached a safe altitude. At this lower altitude they were then able to start the APU and use it as a source of bleed air to restore cabin pressurization, allowing them to continue to their destination.

Both engines are used to supply conditioned air, although other sources of bleed are available at various stages of flight. On the ground, many airports in hot locations provide bleed air through a big yellow pipe when parked on a stand.

This provides the aircraft with air conditioning without the need for us to use the noisy APU.

– Anti Ice Via Air Tubes

thermal anti icing, aircraft windshield anti ice, anti ice system on airplanes, anti icing and deicing, anti icing and deicing system, anti icing products, anti icing equipment, de icing anti icing